Lean manufacturing makes use of various lean tools for improvement in production effectiveness and efficiency. The main goal of such an approach is to get the maximum output by making use of less time, less effort and fewer resources, that is, to create a Lean process. Continual improvement is an important part of every operation and the same can be achieved by applying the lean tools. Some of the commonly used Lean tools in manufacturing are as follows:

- Kaizen

- Poka-Yoke

- Jidoka

- Gemba

- Kanban

- Single Minute Exchange of Die (SMED)

- Total Productive Maintenance (TPM)

- Overall Equipment Effectiveness (OEE)

In continuation our series, this article discuss about Single Minute Exchange of Die (SMED) in detail:

Single Minute Exchange of Die (SMED)

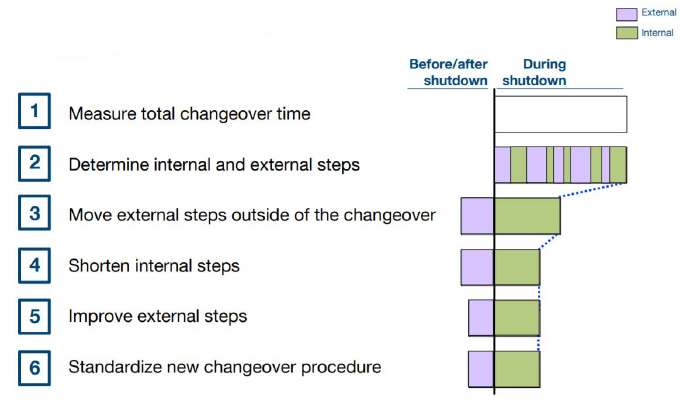

SMED is the process for changeover of the production equipment in the least possible time to less than 10 minutes. The SMED approach can be depicted pictorially as follows:

Single-Minute Exchange of Die approach

- Total time for changeover to be calculated and recorded on an analysis sheet

- Internal steps are the process steps which occurs when the production is shut down like the removal of dies, blade changing, loosening/tightening of bolts etc. External steps are the steps which can be performed during the production like cleanup, tool preparation, subparts assembly, paperwork etc.

- The external steps can be moved outside so that extra time will not be spent in the process.

- Internal steps can be shortened. For example, tools from the toolbox can be displayed on the tool board close to the equipment for ease of access.

- External steps to be improved to eliminate waste. For example, usage of standardized preparation checklist to coordinate activities.

- New standards established should be tracked rigorously for its implementation to reduce variability and for additional improvements.

Single Minute Exchange of Die helps in reducing waste in the manufacturing process by providing an efficient and rapid method of changeover reducing Mura and output variability. SMED is beneficial for lowering the manufacturing cost, reducing inventory levels and smoother start-ups.

.png

)