Lean manufacturing makes use of various lean tools for improvement in production effectiveness and efficiency. The main goal of such an approach is to get the maximum output by making use of less time, less effort and fewer resources, that is, to create a Lean process. Continual improvement is an important part of every operation and the same can be achieved by applying the lean tools. Some of the commonly used Lean tools in manufacturing are as follows:

- Kaizen

- Poka-Yoke

- Jidoka

- Gemba

- Kanban

- Single Minute Exchange of Die (SMED)

- Total Productive Maintenance (TPM)

- Overall Equipment Effectiveness (OEE)

In continuation our series, this article discuss about Overall Equipment Effectiveness (OEE) in detail:

Overall Equipment Effectiveness (OEE)

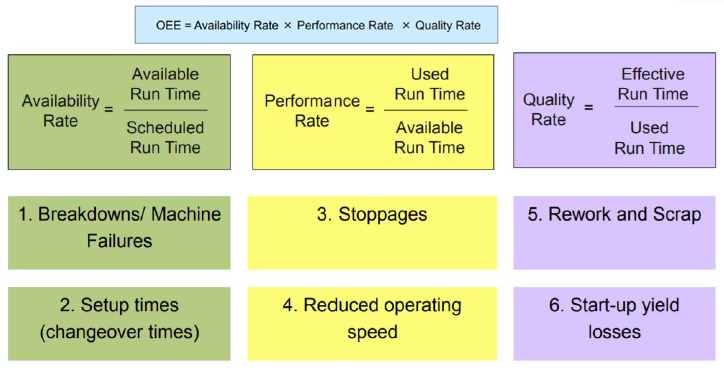

OEE is a key metric tool for managing equipment intensive production processes. It is calculated from the following three elements:

- Availability Rate (measures downtime loss from equipment failure)

- Performance Rate (measures operating speed losses)

- Quality Rate (loss due to rework and scrap)

Fig. Formula for calculating Overall Equipment Effectiveness

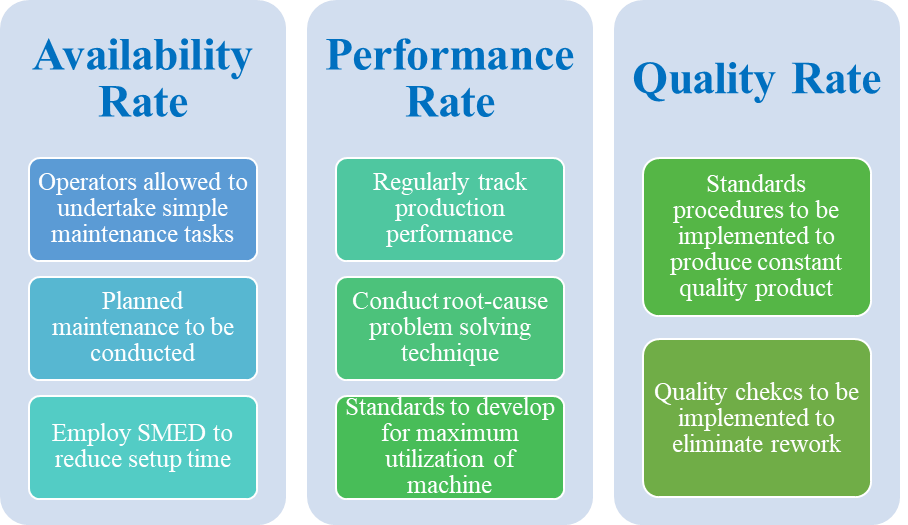

Overall Equipment Effectiveness gives a measure of the system productivity by providing information on the availability of the process, process speed and process quality. 100% OEE means that good quality parts are produced. OEE can be enhanced by improving the Availability, Performance and Quality Rate which can be described as follows:

Fig. Improvement in Availability Rate, Performance Rate and Quality Rate

Overall Equipment Effectiveness gives an important insight on how the manufacturing process can be improved. It can be used for identifying losses, as a benchmark tool and for eliminating waste. It helps in increasing customer satisfaction through improved product quality.

The Lean tools helps to maximize the value of the process/product and to be delivered at a faster rate. These becomes more powerful when collaborated among the team. They are used for continual improvement of the process and helps in ensuring competitive stay in the market by reducing waste and maximizing the profit.

.png

)