As per ICH Q9 “Quality Risk Management is a systematic process for the assessment, control, communication and review of risks to the quality of the product throughout its life cycle.” There are many methods and tools to perform Quality Risk Management. It is important to understand that none of the tool or set of tools are sufficient to address every situation of Quality Risk Management. Some of the important tools are as follows:

- Basic Risk Management Facilitation Methods

- Failure Mode and Effects Analysis (FMEA)

- Failure Mode, Effects and Criticality Analysis (FMECA)

- Fault Tree Analysis (FTA)

- Hazard Analysis and Critical Control Points (HACCP)

- Hazard Operability Analysis (HAZOP)

- Preliminary Hazard Analysis (PHA)

- Risk Ranking and Filtering

- Supporting Quality and Statistical Tools

Preliminary Hazard Analysis (PHA) is a detailed risk analysis technique performed to identify all the potential hazards and events which may lead to an accident. The hazards are ranked according to their severity and follow up actions are taken to control them. It was introduced in 1966 after the Department of Defense of the United States of America requested to perform safety studies at all stages of product development. PHA are sometimes called as Rapid Risk Ranking or Hazard identification (HAZID). It is used in the early stages of a project (like setting up of a new plant). During PHA analysis the hazardous components, safety, environmental constraints, system functionality, facility, equipment’s, personnel competency, diagnostic and emergency procedures shall be considered. Main steps for PHA procedure are:

- PHA prerequisites

- Hazard identification

- Consequence and frequency estimation

- Risk ranking and follow-up actions

PHA prerequisites

This step consists of establishing PHA team, defining & describing the system to be analyzed and collecting risk information from previous similar systems.

- PHA team consists of a team leader (who is experiences with the methods to be used), secretary (who reports the results) and 2-6 team members (who can provide necessary experience and knowledge regarding the system analyzed). The number of team members participating in the analysis depends on the complexity and objective of the system. Some of the team members may participate only in part of the analysis procedure.

- Description of the system include defining the system boundaries, layout drawings, process flow diagrams, block diagrams, handling of hazardous materials, environmental & operational conditions and system detection method for controlling hazards

- System familiarization included knowing as on what the system depends on (inputs), the activities performed by the system (functions) and the services provided by the system (output).

The system is often split into feasible parts to identify all the events and hazards in the system. For example, the system breakdown can be into system parts, activities and risks exposed. Brainstorming technique are usually used to discuss the design or operation of the system.

PHA worksheet is used to report the results obtained from the PHA analysis. A common PHA worksheet used is as follows:

The aforesaid worksheet is just a typical used worksheet. Certain other columns may be added to it as per the requirement of the system.

Hazard Identification

All possible accidents and hazards must be identified. Every system parts, maintenance operations, safety systems, operational modes etc. shall be considered and recorded. A hazard checklist may be used for hazard identification. Some of the common causes of hazards are:

- Mechanical moving parts

- Toxic gases and liquids leaking from the containers

- Deterioration during storage

- Human error

- Fire and explosion

- Noise of supersonic/sub-sonic vibrations

- Biological hazards

Identification of hazards are particularly important to prevent risks in the system. These can by identified by:

- Examining and reviewing similar systems

- Considering interaction between systems

- Review of operation specifications

- Considering environmental factors

- Brainstorming session with the team

- Worst case scenario should be considered

- Consider usage mode changes

Data from the past can also aid in prediction of the possible hazards that can happen, for e.g.- previous accident reports/statistics, near miss reports or reports from governmental bodies can be considered. Expert judgement should be acknowledged. After completing hazard identification, assessment of the possibility and severity is necessary to suggest measures on curbing the risks.

Consequence and Frequency estimation

Risk associated with an accidental event is a function of the frequency of the event and the severity of its potential consequences. For establishing the risk, the frequency and the severity of every accidental event must be determined. Severity of the event can be classified into 4 classes:

| Rank | Severity Class | Description |

| 4 | Catastrophic | Major injury or death of the personnel |

| 3 | Critical | Minor injury to personnel, personnel exposed to harmful radiation & chemicals/fire, release of chemical into the environment |

| 2 | Major | Low level of exposure to personnel, activation of facility alarm system |

| 1 | Minor | Minor system damage but no injury to personnel, allow any kind of exposure to operational or service personnel or allow any release of chemicals into the environment |

The frequency estimated should be related to the severity of an average consequence of each particular accident event or in case of specific worst case then frequency is estimated of the event producing a specific event involving combined assessment (e.g.- probability of the accidental event and personnel is a combined assessment in case where the personnel was not able to escape). Therefore, in an accidental event, there maybe several consequences with associated frequencies. The frequency of events may be classified into broad classes.

Risk ranking and follow-up actions

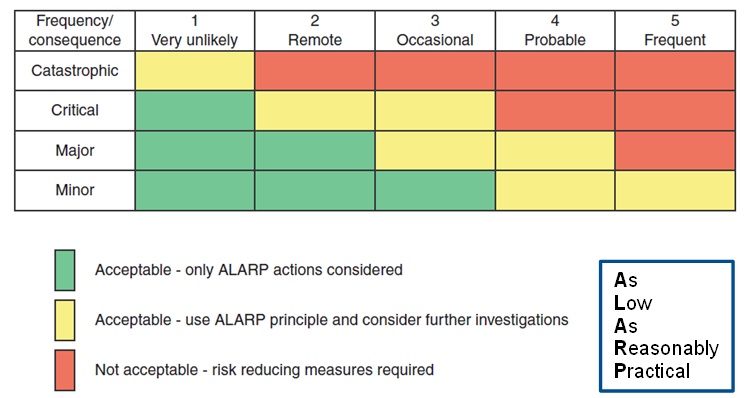

Risk is established as a combination of an event/consequence and severity of the same event/consequence. Risk matrix for the same is constructed as illustrated below:

Risk levels may be assigned to specific risks and actions to be done can be defined for them as:

| Level | Name | Description |

| H | High | High risk and not acceptable. Further analysis shall be performed. Process should be redesigned/changed if risk is still unacceptable |

| M | Medium | Risk maybe acceptable but shall be redesigned/changed to make it reasonably practical and further analysis shall be performed |

| L | Low | Risk is low and further risk reducing measures are not required |

PHA shall be reviewed or updated whenever new information is known about the system, system is modified, maintenance or operating procedures are changed, in cases of mishap or near miss, change in environmental conditions and change on operating parameters. The results obtained in the decision making is used to judge acceptability and as an improvement opportunity.

Advantages of PHA:

- Helps in ensuring safety of the system

- Hazards are detected at the early stage of project development

- Provides basis for design decisions

- Design time decreased by reducing number of inappropriate events

- Modifications are easier and less expensive to implement at the initial stages of the design

Preliminary Hazard Analysis is applicable to any activity or system. It is a high-level risk analysis tool used in the early stages of project development.

.png

)